“The value of nanoparticle technologies have historically been difficult to reach. The Motley Fool, not so incorrectly, observed that “Scientists like to joke that the promise of nanotechnology has been five years away for the last 35 years.”

Why Does Small Matter?

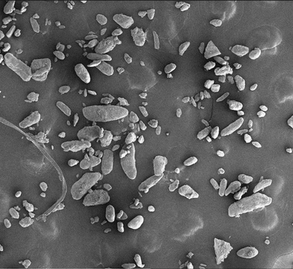

BLH Ecology Concepts has spent the past eight years developing and refining a method for the creation and harvesting of extremely small particles in a manner that lends itself to continuous process applications. Our review of the literature confirms that this process represents a significant discovery in the area of nanotechnology and creates an efficient environment for the production of extremely small particles. The process has a broader application than that existing under current techniques and, as a result, expands the types of materials that can be addressed and the number of applications for which these micronized materials may be relevant. This process overcomes many of the limitations of the current techniques including: 1) the inability to produce significant volumes of particles of uniform size through a continuous process and; 2) to harvest/filter particles in a primarily batch environment.

20

Standard For

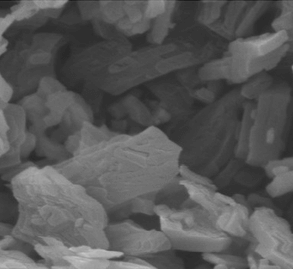

Jet Milling and Wet Milling.

-100

BLH ECOLOGY

Changing The Way Matter Is Manipulated.

The promise of the benefits of nanoparticles has been hampered by the inability to produce large volumes of the particles in a cost efficient manner. The patent pending technology developed by BLH Ecology produces particles through a continuous process and permits harvesting of the particles without the use of filters or membranes.

THE BLH DIFFERENCE

Through its continuous process technology, BLH is able to achieve an efficient yield of nanoparticles from the target material and to capture the output.

Adjustability

Increased

Yield

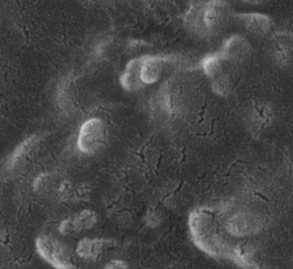

Reduced Agglomeration

Direct Harvesting

Applicable to a Broad Range of Materials

Uniformity of Particle Size

Dramatically Improved Economics

BLH Process Impacts Many Classes of Materials

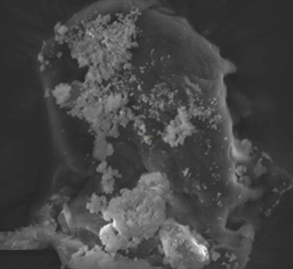

Inorganic

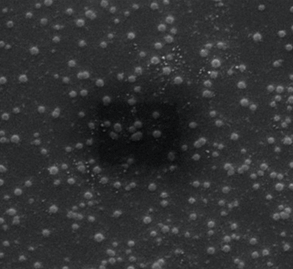

Beginning 8-10 Microns to

BLH 70-90 Nanometers

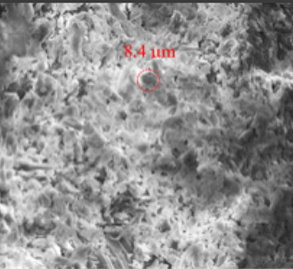

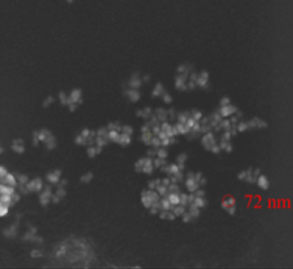

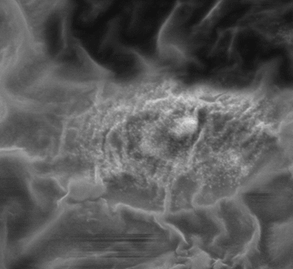

Organic

Beginning 8.4 Microns to

BLH .72 Nanometers

Organometallic

Beginning 7 Microns to

BLH 90 Nanometers

Biologic

Beginning 6 Microns to

BLH 30 Nanometers

Current Science

To meet the increasing commercial demand for small particles and reap the advantages such particles can impart in a growing catalog of applications, a number of methods, both mechanical and chemical, have been developed for the creation of submicron particles.

Included among the techniques being pursued and refined are a number of processes that utilize the properties and environment of supercritical carbon dioxide (scCO2) in the creation of nanoparticles, the most widely used of which are Rapid Expansion Supercritical Solution (RESS) and Supercritical Anti-Solvent (SAS).

Regardless of which current technique is utilized to produce the nanoparticles, that production is limited to labor intensive, low yield batch processed. Additionally, the recovery of the final particles remains a limitation in any of the current processes.

Meet Our Team

BLH Ecology | Experienced, Dedicated Professionals